May 2005

Wednesday 18th May 2005

I hadn't done much to the Hog over the last few months except for entering it into the Brighton Modelworld exhibition 2005 in February. It was now May, and time was drifting on so I felt it was probably about time that I repaired the damage I'd received at the show back in February. What really prompted me to make a start was that the local Scouts group had asked me to show the Hog at one of their evening sessions in early June and a local primary school had also asked if I could show off the Hog during their summer fayre in July.

|

The main damage was to the motor controller that had given off a lot of sparks and smoke while self destructing at the end of the Brighton show. It wasn't hard to locate the damaged items because they were well and truly black and burnt. After dismantling the MOSFET bricks and replacing the obviously damaged components I was left with this little pile of crispy items. |

|

I had also noticed a few burnt resistors in the pre-amp driver stage so replaced these together with a couple of transistors that had split themselves apart.

With motor controller back together in the Hog, I gave it a quick test. The motors seemed to be working fine for a few seconds, but sadly there was then a very bright light coming from the MOSFET bricks, followed by a plume of smoke and a horrible burning smell. It was a bit disappointing after all the time that I had just spent to find there was still more problems, but I had lost the motivation today to do any more repairs and put off the post mortem to another day.

June 2005

Wednesday 1st June 2005

After the disappointing result of my first attempt to repair the motor controller, I pulled it to pieces again and found another six MOSFETs had blown, together with one pre-amp transistor. I wasn't sure why these had blown, but I had noticed that on some of the MOSFETs the insulating thermal gaskets were split and the transistors were making electrical contact with the heat sink when they shouldn't have been. If this was the case, then this might explain the sudden increase in blown MOSFETs, particularly after I had included a current limiter specifically to stop this sort of thing happening. In either case, I replaced the damaged gaskets and all the blown components and hoped all would be well.

Luckily this time when I tried the controller again, all worked well and there were not sparks or smoke. I now felt confident about being ready for the Hog's next outing to the local Scouts group in a couple of weeks time.

July 2005

Over the last few weeks the Hog has been out on show at three of the local schools. Firstly it was on static display at Downlands school in Hassocks. After that, I was asked to run it around the playground at Ditchling Primary school. To make it a bit more interesting, I took the Hassocks Hog 1 there as well so that Hog II could bully it around a bit.

The demo was going well until all of a sudden there were a lot of clicking noises and one drive looked like it was in trouble. A few moments later there was a puff of smoke and the other drive stopped completely, leaving the Hog only able to go round in circles. Luckily this was after I had tossed Hog I around for a bit, but I was dreading finding out what had gone wrong. I had a nasty feeling that the puff of smoke might have been another batch of MOSFET self-destructing.

After a close inspection back at home, I established what the clicking noises I heard were from a locking pin in the motor sprocket. This was fairly quick to resolve by replacing the pin with a new one, so one drive was back in action.

|

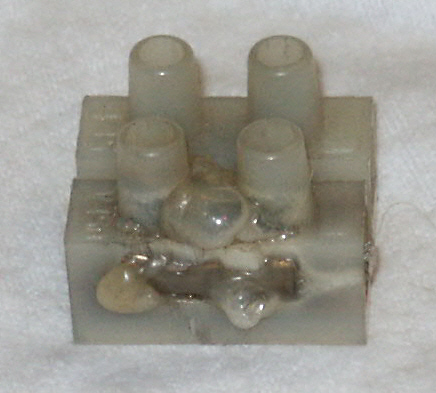

After a bit more probing, I figured out that the puff of smoke was luckily not from the MOSFET, but was instead from one of the connectors between the motor and the motor controller. A screw must have worked loose allowing the wires to arc, which in turn began to get hot and eventually melt the plastic. The picture on the right shows what was left of the connector after it had finally melted and insulated the wires from the metal clamp inside. It was a simple case of replacing the connector with a new one, and both drive were now back up and running. |

|

The third Hog's outing was at the Hassocks Infants school fayre where I was asked to demo it in the playground. Again I brought along Hog I to bully about. The demo was going well when all of a sudden I lost one drive when a chain jumped off the sprocket. I was able to put the chain back and continue the demo, but it wasn't long before it again jumped off. By this time the batteries were starting to get a bit low, so the demo came to a natural end.

Later back in the garage I looked at why the chain had jumped off, and could only put it down the the chain having stretched a bit with age. Unfortunately there was not enough movement left on the axle adjustments to take the slack up, so I had to think of another way of taking up the slack.

|

After a bit of head scratching I decided to use some strips of 12mm polypropylene as a chain tensioners. I heated them up with my trusty hot air paint stripper so that I could put a nice curve in them. I then found a suitable locations to bolt the strips to in such a way that they created a nice curve in the slack section of the chain. It is not easy to see this in the adjacent photo, but the tensioner is the white strip right in the middle of the picture. The tensioner seemed to work OK in the garage, but I have yet to try it out in anger. |

|

August 2005

For a while I have been thinking about re-designing the Hog's motor controller so that it doesn't use a specially modified radio receiver. To do this, I will be looking at using a difference micro-processor with plenty of I/O so that I can look at all the individual servo channels rather than a single data stream. Having done a bit of surfing on the Internet I came across the company IAR System that supply a host of development systems. I dutifully sent them an email telling them about my plan to re-design the Hog's motor controller, and asked if they would be interested in sponsoring me with this re-design by donating a development system. Edward was extremely helpful and kindly agreed to send me an evaluation kit for the Atmel AT91 series processors in exchange for a link to there website. Thanks IAR, your generosity is very much appreciated!